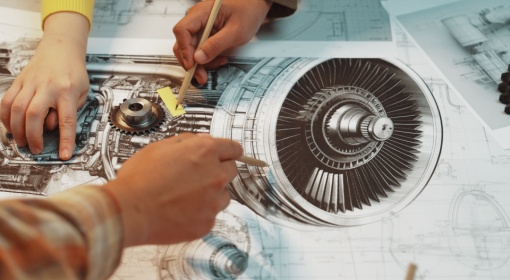

As the demands on manufacturing sites grow yearly, key stakeholders continuously innovate to improve operations efficiency and stay competitive.

Challenge

With minimal margin for error in the aerospace industry, production partners are working closely with carriers to create fully optimized production lines and facilities. Our client, a global carrier, identified a key concern at one of their supplier’s production sites when they realized that several data sources were fed into one process, leading to production errors.

Why Quest Global?

Digital twin innovation drives manufacturing efficiency to a whole new level

By developing a digital twin or virtual model of the production environment, the manufacturing process could be simulated, ensuring errors were identified and ultimately reduced. With our exceptional track record in aerospace, our team at Quest Global was identified as the engineering specialist with the sector insight to solve this problem. Our team designed a Digital Twin of the site, which would provide the insight and capacity to accelerate part production, optimize design, and reduce machine programming time.

Solution

With Quest Global’s bespoke smart manufacturing solution, our client can:

- Work with a custom-designed Digital Twin of components and assemblies created with insight and expertise

- Benefit from bespoke end-to-end technology with offline virtual portfolio and industrial domain expertise

- Be Confident in a solution based on best practices and standard work protocols tailored for Model-Based Enterprise or MBE

- Deploy this solution successfully at their supplier’s production site and potentially apply and adjust for other production facilities where required

- Use simulations to gain a complete understanding of key functions like metal cutting, lab-based inspections, and other validation and verification processes

- Gain from high levels of interoperability and collaboration with a variety of platforms, ensuring greater flexibility

Results – At A Glance

- An accelerated production environment ensures critical parts are realized 44% faster than traditional manufacturing

- Custom-built Digital Twin decreases manufacturing design cycle by 30%

- Accurate simulation can reduce machine programming time by 80%

- Futuristic adaptive closed-loop manufacturing is successfully enabled, maximizing efficiency

- Predictive analytics can now be applied to minimize non-conformance levels on manufacturing sites

- Gateway established for connecting to the external supply chain of OEMs

Chris Hardgrave joined Quest Defense in April 2024 as Vice President for Strategic Accounts. He is responsible for sales, growth, and development of strategic relationships for new business development efforts in the Aerospace and Defense sector. Chris works in the Washington, D.C. office.

Chris Hardgrave joined Quest Defense in April 2024 as Vice President for Strategic Accounts. He is responsible for sales, growth, and development of strategic relationships for new business development efforts in the Aerospace and Defense sector. Chris works in the Washington, D.C. office.

As Chief Engineer for Quest Defense, Jon is responsible for ensuring that sound engineering processes are maintained and followed by our employees working in a diverse set of services and disciplines across all verticals. In this role he also leads Quest Defense’s efforts to develop new methods and technologies to help grow the business through innovation, as well as building and promoting the technical reputation of the company in the public sphere.

As Chief Engineer for Quest Defense, Jon is responsible for ensuring that sound engineering processes are maintained and followed by our employees working in a diverse set of services and disciplines across all verticals. In this role he also leads Quest Defense’s efforts to develop new methods and technologies to help grow the business through innovation, as well as building and promoting the technical reputation of the company in the public sphere. Jeff Fischer serves as a board member for Quest Defense Systems and Solutions business. Additionally Jeff is the Operations Leader for the Quest Global Aerospace and Defense Industry.

Jeff Fischer serves as a board member for Quest Defense Systems and Solutions business. Additionally Jeff is the Operations Leader for the Quest Global Aerospace and Defense Industry.

Steve Gerber is President and CEO of QuEST Defense Systems and Solutions business and is responsible for providing the leadership and growth of this venture.

Steve Gerber is President and CEO of QuEST Defense Systems and Solutions business and is responsible for providing the leadership and growth of this venture. Joe supports Special Missions across Quest Global to include key client contract negotiations, strategic business solutions, M&A, and culture endeavors.

Joe supports Special Missions across Quest Global to include key client contract negotiations, strategic business solutions, M&A, and culture endeavors.

Frank Kendall is an independent consultant to defense industry firms and non profit research organizations. He is a Senior Fellow at the Center for American Progress, a Senior Advisor to the Center for Strategic and International Studies, and a member of th e Council on Foreign Relations. Among other industry positions, he is a member of the board of directors of Leidos Corporation and of Leonardo Electronics USA Inc. From 2012 to 2017, Mr. Kendall served as the Under Secretary of Defense for Acquisition, T echnology and Logistics (AT& after serving as the Principal Deputy Under Secretary from 2010 2012. Mr. Kendall has over 45 years of experience in engineering, management, defense acquisition, and national security affairs in private industry, governmen t, and the military.

Frank Kendall is an independent consultant to defense industry firms and non profit research organizations. He is a Senior Fellow at the Center for American Progress, a Senior Advisor to the Center for Strategic and International Studies, and a member of th e Council on Foreign Relations. Among other industry positions, he is a member of the board of directors of Leidos Corporation and of Leonardo Electronics USA Inc. From 2012 to 2017, Mr. Kendall served as the Under Secretary of Defense for Acquisition, T echnology and Logistics (AT& after serving as the Principal Deputy Under Secretary from 2010 2012. Mr. Kendall has over 45 years of experience in engineering, management, defense acquisition, and national security affairs in private industry, governmen t, and the military. John Thackrah is the founding Principal of Sextant Solutions LLC, an aerospace, maritime and government acquisition consultant.

John Thackrah is the founding Principal of Sextant Solutions LLC, an aerospace, maritime and government acquisition consultant. Page Hoeper is a private consultant, corporate director, and venture capitalist. Since leaving government service, Mr. Hoeper has focused on corporate governance and board service. He chairs the boards of OnPoint Technologies, Inc., 501c(3) venture capital fund established by Congress to focus on emerging commercial technologies of interest to the U.S. Army, and Quest Defense Systems & Solutions, a provider of engineering services to the U.S. defense industry.

Page Hoeper is a private consultant, corporate director, and venture capitalist. Since leaving government service, Mr. Hoeper has focused on corporate governance and board service. He chairs the boards of OnPoint Technologies, Inc., 501c(3) venture capital fund established by Congress to focus on emerging commercial technologies of interest to the U.S. Army, and Quest Defense Systems & Solutions, a provider of engineering services to the U.S. defense industry. As the President of Quest Global, Bob is responsible for establishing and maintaining senior customer relationships, catalysing new business development, and overseeing innovative and transformational deals. In this role, he also assists in building relationships with strategic acquisitions for the company.

As the President of Quest Global, Bob is responsible for establishing and maintaining senior customer relationships, catalysing new business development, and overseeing innovative and transformational deals. In this role, he also assists in building relationships with strategic acquisitions for the company.